Tool manufacturing is a testament to precision and resilience. For tools, be they fashioned from metal or plastic, their primary mandate is to resist formidable forces, ensuring seamless functionality through every use. Delving deeper into a tool’s capability, we encounter tensile testing. This intricate process grants manufacturers a comprehensive look at the intrinsic properties of their chosen materials, with the aid of specialized tensile equipment. Such devices meticulously mirror the real-world stresses tools encounter, ensuring they’re up to the task.

Understanding Tensile Testing

At its core, tensile testing, sometimes called tension testing, is a mechanical procedure that examines a material’s endurance by stretching it until it breaks. The aim here isn’t just to witness its breaking point but to uncover various attributes such as its elasticity, deformation, and the relationship between stress and strain. Such rigorous testing facilitates informed decisions when choosing materials for specific applications. Moreover, it’s pivotal for quality assurance and offers a predictive lens into material performance under varied forces.

The Importance of Tensile Testing in Tool Manufacturing

Several factors underscore the importance of tension testing in tool manufacturing:

- Quality Assurance: At the forefront is the assurance of impeccable quality, confirming that materials align with set standards.

- Guided Product Development: Tensile tests elucidate materials’ behavior, enabling the selection of optimal materials tailored for specific tools.

- Upholding Safety Protocols: An intimate understanding of a material’s tensile strength is instrumental in ensuring tools adhere to established safety guidelines.

A Closer Look at the Tensile Testing Process

The tensile testing procedure can be broken down into several stages:

- Sample Curating: A specimen is crafted using tensile equipment, conforming to internationally recognized standards to guarantee testing precision. This process benefits from specialized machines. Round specimen preparation machines ensure the optimal shaping of round samples, while flat specimen preparation machines prepare flat samples to the highest standards.

- Securing the Sample: This specimen is then affixed to a tensile testing machine, tightly clamped from both ends.

- Force Application: The tensile machinery exerts a calibrated force on the specimen, stretching it until it fractures.

- Data Aggregation: Concurrently, as the specimen is subjected to this force, the machine diligently records the material’s reactions, capturing metrics like its elongation and the force magnitude at its breaking point.

- Dissecting Data & Documentation: Post-testing, the collated data undergoes thorough scrutiny, extrapolating vital data points such as yield strength and ultimate tensile strength. This assessment often culminates in an exhaustive report for archival and compliance purposes.

Advanced Tensile Equipment in Modern Tooling

Tensile testing’s accuracy and reliability are deeply intertwined with advanced equipment. The arena of tool manufacturing has seen a surge in innovative machines designed specifically for this purpose. Key among these are:

- Universal Testing Machines (UTM): UTM stands as the linchpin in tensile testing. These machines meticulously apply known stresses to test specimens, ensuring a material’s strength and elasticity are accurately measured. With the advent of technology, modern UTMs come equipped with digital interfaces and sophisticated software, enabling precise test regulations and real-time data analytics.

- Extensometers: A vital tool in the tension testing arsenal, extensometers measure minute changes in the length of a specimen as it undergoes stress. Advanced extensometers can provide data down to microscopic levels, allowing for a deeper understanding of material properties.

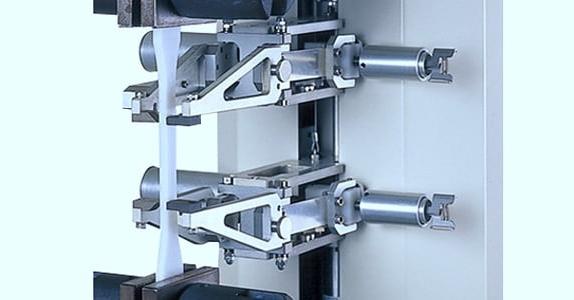

- Securing Devices: Essential for a controlled test, grips and fixtures hold the test specimen securely, preventing any unintended movement. The choice of securing the device can vary based on the material under test and the magnitude of force it’s subjected to. Some are specifically designed for brittle materials, while others cater to more ductile substances.

- Environmental Chambers: Often overlooked but crucial, environmental chambers mimic varying atmospheric conditions, be it extreme temperatures, humidity levels, or even corrosive environments. By simulating these conditions, manufacturers gain insights into how materials would fare in different real-world scenarios, thereby ensuring their products are robust across a spectrum of environments.

In the evolving realm of tool manufacturing, as materials diversify and applications become more complex, the need for advanced tensile equipment becomes even more paramount. These tools ensure product quality and safety but also propel the industry toward innovation and excellence.

Tensile testing serves as a pivotal mechanism in ensuring the durability, safety, and efficacy of tools crafted for diverse applications. By meticulously examining a material’s inherent properties and endurance threshold, manufacturers can make well-informed decisions that significantly impact a tool’s longevity and functionality. Beyond its technical ramifications, tension testing instills confidence among consumers and stakeholders, assuring them of the reliability of the products on the market. As the manufacturing sector continues its innovation trajectory, the rigorous standards set by tensile testing will undoubtedly remain an indispensable benchmark. This will guide the industry toward excellence and reinforce its commitment to quality.